Introduction

- The concept of

evaporative cooling is known for centuries and is quite popular in dry hot climates. It provides for a very effective

cooling at a very low energy cost and minimum capital expenses.In selecting an evaporative cooler, the following

characteristics need to be considered:

- Cooling Efficiency, i.e.

the absolute physical limit of the lowest temperature achieved by the

cooler under the most extreme conditions.

- Equipment Cost Efficiency,

i.e. the cost of the equipment required to cool a defined space.

- Operating Cost Efficiency,

i.e. the cost of energy, water supply, consumable materials, preventive

maintenance etc., required to operate a given cooler.

- Quality & Safety,

which

have extra importance in coolers due the inherent combination of water and electricity

handling in a consumer environment.

-

The MAGICOOL represents a major

breakthrough in evaporative cooling technology and is

superior to conventional coolers in all the above

categories.

MAGICOOL Evaporative Coolers

Principles of operation

-

The MAGICOOL combines a special type

of absorbing material with a unique geometry of the "wet region" to

generate an extremely efficient cooling system. The moisturizing module

consists of parallel porous plates with extremely high capillary effect,

which causes the homogeneous distribution of water over the plates

surface, while water is supplied at the edges of the plates. The proper

choice of material ("media") provides water rise in the plates even

against the force of gravity.

-

The spaces between the plates form

rectangular channels for air flowing through them. In contrast to

conventional coolers, air in the MAGICOOL technology is flowing in

parallel to the plates rather than perpendicular to them. This geometry

allows reducing the air pressure drop even for plates spaced about 2 mm

apart. A blower (fan) forces relatively dry air through these channels

causing the water contained in the plates to evaporate adiabatically,

producing a very humid air flow (up to 92% R.H.) and consequently a much

reduced temperature. The capillary effect of the porous plates

eliminates the need for an additional water pump and re-circulating

mechanism. The large contact area between the air flow and the wet

surface serves to achieve almost ideal conversion efficiency without

increasing the air flow resistance. As a result MAGICOOL technology

provides for the design of an extremely wide range of coolers, from

units of few thousand CFM to systems of tens of thousands CFM. The spaces between the plates form

rectangular channels for air flowing through them. In contrast to

conventional coolers, air in the MAGICOOL technology is flowing in

parallel to the plates rather than perpendicular to them. This geometry

allows reducing the air pressure drop even for plates spaced about 2 mm

apart. A blower (fan) forces relatively dry air through these channels

causing the water contained in the plates to evaporate adiabatically,

producing a very humid air flow (up to 92% R.H.) and consequently a much

reduced temperature. The capillary effect of the porous plates

eliminates the need for an additional water pump and re-circulating

mechanism. The large contact area between the air flow and the wet

surface serves to achieve almost ideal conversion efficiency without

increasing the air flow resistance. As a result MAGICOOL technology

provides for the design of an extremely wide range of coolers, from

units of few thousand CFM to systems of tens of thousands CFM.

-

Due to the above described

constructions and the fact that capillary effect is used to distribute

the water over the plates, the cooler has an inherent self adaptation

effect, i.e. the water supply adjusts itself to the water evaporation

rate, a wide range of inlet, air temperature and humidity.

-

One of the typical problems

of conventional coolers is the effect of salts build-up on the evaporation

surfaces, reducing cooler's performance. This effect is an intrinsic

feature of commonly used technology, in which there is a continuous supply

of water (with dissolved salts in it) to the evaporation surface, where

water evaporates, leaving the salts on the surface. MAGICOOL technology

allows for a drastic reduction of this effect. The physics of MAGICOOL

action maintains a continuous water film connecting the porous evaporation

surface with the water reservoir, so that salts ions can move due to

diffusion from sites with high ion concentration (evaporation zone) to

the those with lower ion content (water reservoir), providing an

efficient way of salts ions removal. This MAGICOOL approach bestows

an additional major advantage over standard technologies.

-

Another health related advantage of MAGICOOL is avoidance of

bacterial contamination. Because of continuous flow of water

(about 3-5 l/h), even the unit is not operating, there is no

situation of stagnant or still water. Thus MAGICOOL meets the

requirements of Ministries of Health, avoiding the risk of

Legionnaire's disease and similar hazards.

-

The MAGICOOL technology allows

approaching to the physical limit of the air temperature drop for any

cooling technology based on water evaporation. The next graph presents

the maximal possible air temperature reduction by evaporation as a

function of the inlet air characteristics. MAGICOOL reduces the air

temperature more then 90% of the values on the graph for the same

conditions. Temperature values presented on the graph are in the

centigrade degrees.

It is easy to see that temperature

drop grows for hotter and dryer inlet air, so that MAGICOOL can reduce

the temperature by up to 15 20°C for desert climate.

-

The cooler is very easy to maintain as

there is only one mechanical moving component the blower, which is very reliable and has a long life span.

-

The frequency of required change of

the evaporative modules (the "media") is dependent upon the water

chemistry.Usually, evaporative modules need to be replaced once in 3 to 5 years.

-

-

-

-

2. The MAGICOOL advantages

-

-

The MAGICOOL evaporation

efficiency as tested by major independent laboratories is 90% or

better. Conventional technologies are at the 60% range.

-

Energy saving is significant

due to the reduced pressure and the elimination of water pumps (resistance evaporative modules Magicool is about 2,2 mm H2O).

-

Water supply is limited to the

exact need due to the self adjusting characteristic of MAGICOOL.

-

Maintenance costs are kept to a minimum due to the

inherent reliability.

-

MAGICOOL technology results in

higher quality as well as safer units. In conventional coolers,

extensive corrosion rate is common due to the water coolers and

safety is always of great concern due to possible water leaks

into electric motors.

-

Short start-up time to the full performance - the air reaches the lower temperature in about 1 min.

-

No dragging out of water droplets by the flow, typical to conventional technology.

-

Avoiding the risk of Legionnaire's disease.

-

Less salt on evaporation surfaces

-

-

-

-

3.

Engineering considerations

The engineering design for the new

coolers models was based on the following guidelines:

-

Modular and simple internal structure, providing high level of

coolers manufacturability

-

Minimal manufacturing cost

-

Maximal conversion efficiency

-

Optimal water and power consumption

-

High reliability and maintainability

-

Simple installation

-

High cost efficiency

-

Fulfilment of all demands of national standards regarding

coolers design and performance

-

While most of these guidelines are of

general objectives for any engineering design, it is important to point

out that the developed models of cooler stand up well to the all above

requirements.

The internal structure of the system comprises of the blower, porous

plates, water reservoirs and water supply and distribution

system. The electrical and mechanical metal components are

situated in a way of minimal exposure to the wet airflow and

well distanced

from the moist zones. Therefore, possible corrosion and

electrical problems are reduced to the minimum resulting in

enhanced endurance, reliability and safety of the design.

The air entering the blower passes through the filter to

remove dust and other particles, which would accumulate on the porous

plates and therefore reduce their efficiency. The air flow filtration

helps to reduce the noise level as well.

-

The process of heat and mass transfer

inside the porous plates and out into the air flow in the channel

between the plates is very complicated and we will not enter the

detailed physical description in this document.

In essence there is a

coexistence of liquid and vaporized water in the plates, which can be

drawn out into the channel by means of pressure gradient which affects the

evaporation rate of the water (this effect will be noticeable only for

flow velocities of more than 10m/sec).

The porous plates, water baths and

upper water distributors are mechanically joined into the module

(Evaporative Module) to provide maximal flexibility in design. The

designer chooses the blower and calculates the inlet area on the base of

predetermined capacity of the cooler and inlet flow velocity. The net

cross section area is the ratio of capacity and flow velocity. These

parameters establish the necessary number of the wetting modules, water

reservoirs and water distribution system characteristics.

The cooler assembly is based on a

strong rigid frame, which serves as a skeleton of the device to carry

the coolers subsystems. The

Specifications

page demonstrates

this concept and show the main measures of the cooler design. The Table

cites the range of the developed coolers models and their basic

characteristics and the photographs on this page show

the main internal structure of

the cooler, as well as

the unique chilled air distribution sleeve.

The

latest models are able to blow the cooled air to the distance up to 25

meters (82 ft).

MAGICOOL units perform successfully in a variety of applications proving the superiority of this innovative

technology. Many satisfied customers can testify for the reliability,

maintainability and cost efficiency of the cooling solutions provided

through the implementation of MAGICOOL technology.

4.

Design considerations and parameters.

Range of MAGICOOL Coolers

Performance - 3,600 35,000 CFM

|

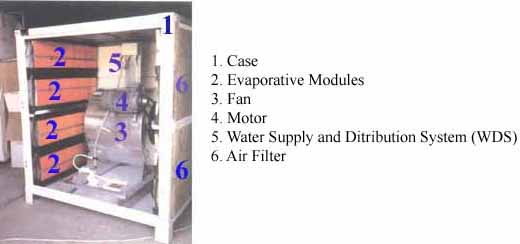

MAGICOOL Units consist of 6 major

subsystems

|

Typical

MAGICOOL Cooler Unit |

|

-

4.1 MAGICOOL Case

The case of the cooler is made of

one of two choices:

-

SS-304 steel sheets

-

White-acrylic oven-coated

galvanized metal sheets.

-

-

-

4.2 MAGICOOL Evaporative Modules.

-

- MAGICOOL coolers are based on capillary effect and

not on the water circulation and, therefore, do not comprise water

pumps.

4.2.1 Evaporative Modules (EM) of

MAGICOOL Coolers consist of plurality of thin plates.

4.2.2 These plates have porous structure,

and highly developed evaporation area.

4.2.3 The pores of the structure are

oriented in such a way, that they create tiny capillary

passages in the plate body with the multiple microscopic

passages to the plates' surfaces.

4.2.4 The plates are separated by special

spacers and are fixed together into the evaporative set.

4.2.5 This set is immersed into the

plastic water reservoir on one its side. The other side of

the set is connected to the water distribution dripping

system.

4.2.6 Evaporative Module is a combined

unit of the evaporative set, water reservoir and the water

distribution dripping system.

4.2.7 Each Evaporated Module (EM) is

designed for performance of 1000CFM

4.2.8 This performance value is key for

the necessary number of EM modules calculations with respect

of the cooler performance. Let us define:

CP Cooler Performance in CFM

EMP Evaporative Module Performance in CFM

N Number of EM's in the Cooler

For example: cooler designed for

the air flow of 25,000 CFM needs 25 EM's. |

-

- 4.2.9 EM material is modified by the

anti-bacterial and anti-mould compound.

-

-

4.3 Fan + Motor

-

-

4.3.1 Fans of

MAGICOOL coolers are standard

fans and are chosen with

respect to the pre-designed cooler performance.

-

-

4.3.2 Fan driving motors are standard electrical

motors.

-

-

4.4 Water Supply and

Distribution System (WSD)

-

-

This system is designed to keep

the EM wet.

5 Manufacturability

-

MAGICOOL Coolers are design for

high level of manufacturability and reparability due to their

modular structure.

-

MAGICOOL evaporative air coolers

are used for many applications and locations:

- Industry

Hygiene and Cosmetics Products Manufacturing Factories

Plastics Plants

Textile Factories

Chemical Plants

Cans Plants

Hot manufacturing sites

- Defense

|

|